The Process

The steps in CarbiCrete’s process are identical to those of conventional concrete making, with a few key differences.

With cement-based concrete, the first step involves mixing cement with aggregate and water. With CarbiCrete, cement is replaced with steel slag, which is mixed with the other materials using standard equipment.

The mix is then poured into a conventional block-making machine where the CMUs are formed.

In order to cure the concrete, it must be placed into a specialized curing chamber into which CO2 is injected. Within 24 hours, the concrete has reached full-strength.

CO2 Curing

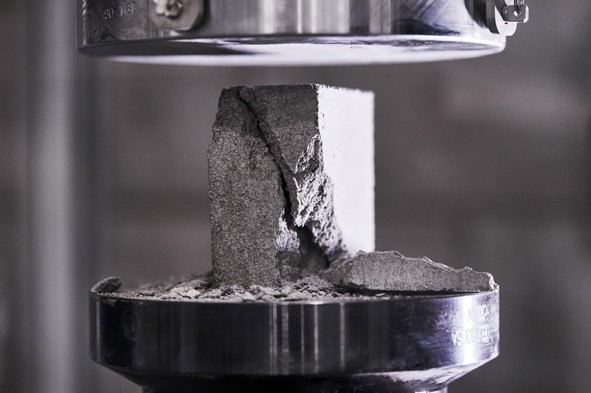

Our patented curing process involves the injection of CO2 into a curing chamber where it reacts with the steel slag within the fresh concrete. During the carbonation process, the CO2 is permanently captured and converted into stable calcium carbonates, filling the voids of the matrix to form a dense structure and giving the concrete its strength.

Learn more about the chemical reaction at the root of our process.

Concrete Properties

When compared with cement-based CMUs, CarbiCrete CMUs exhibit equivalent or better mechanical and durability properties. They have the same water absorption properties, but higher compressive strength by up to 30% and display better freeze/thaw resistance. CarbiCrete CMUs meet or exceed ASTM C90 performance requirements.

Lifecycle Assessment

CarbiCrete’s net carbon-negative impact has been validated by a third-party verifier. It starts with a 100% reduction of carbon dioxide emissions associated with cement production. It drives net negative emissions with the permanent sequestration of carbon dioxide that is mineralized in the product during curing. Even when additional transportation and conversion impacts are considered, CarbiCrete’s full LCA results in net carbon-negative concrete products.

Concrete Makers

Implementing CarbiCrete technology in your masonry or hardscape plant is a winning proposition for you, your community and the environment. Learn about how CarbiCrete can help you increase sales while reducing the embodied carbon of your products.

Designers & Builders

Replacing cement in the concrete mix presents the single biggest opportunity for reducing embodied carbon in the built environment. Learn more about how CarbiCrete can lower the embodied carbon of your construction project.